Items

Items

Creator is exactly

Ritchie, Samuel J

-

[CJ502AAA], Letter from Samuel J Ritchie to Thomas Alva Edison, August 30th, 1900

1900-08-30 -

[CJ502AAB], Telegram from Samuel J Ritchie to Thomas Alva Edison, September 1st, 1900

1900-09-01 -

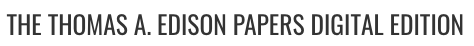

[D8845ACD], Letter from Samuel J Ritchie to Charles Batchelor, July 16th, 1888

1888-07-16 -

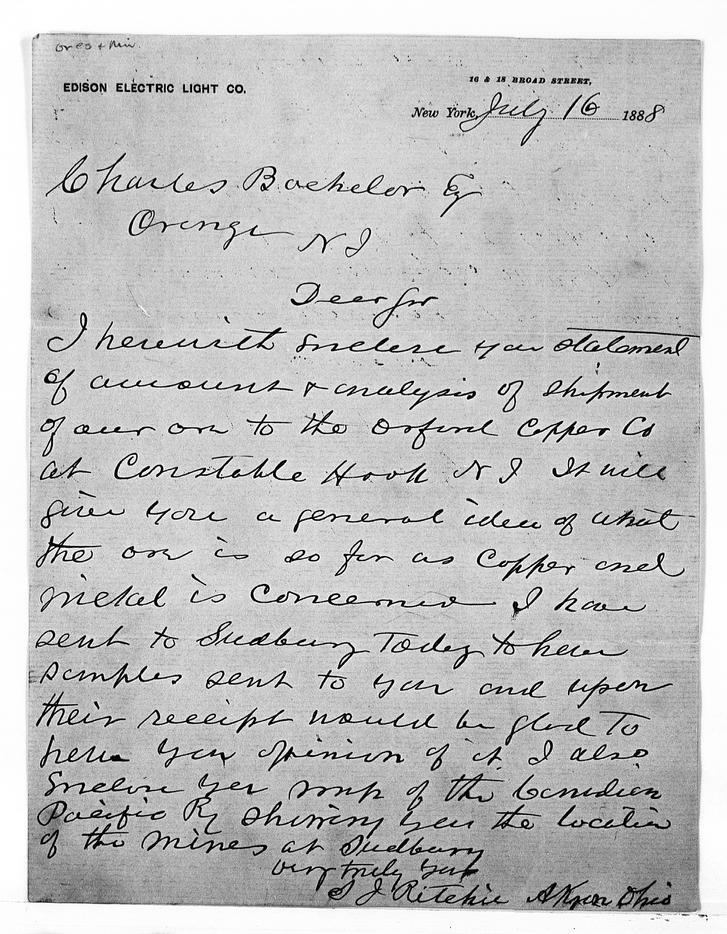

[D8845ACF], Letter from Samuel J Ritchie to Charles Batchelor, July 16th, 1888

1888-07-16 -

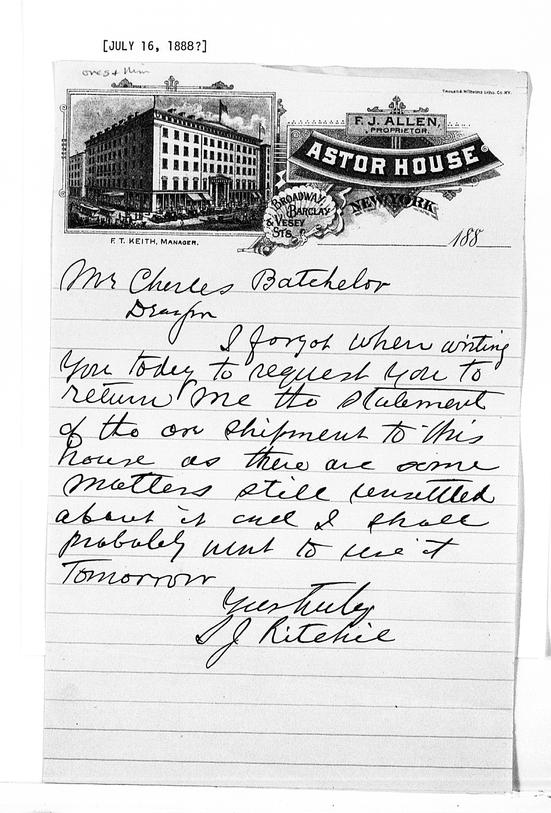

[D8952AAH], Letter from Samuel J Ritchie to Thomas Alva Edison, January 19th, 1889

1889-01-19 -

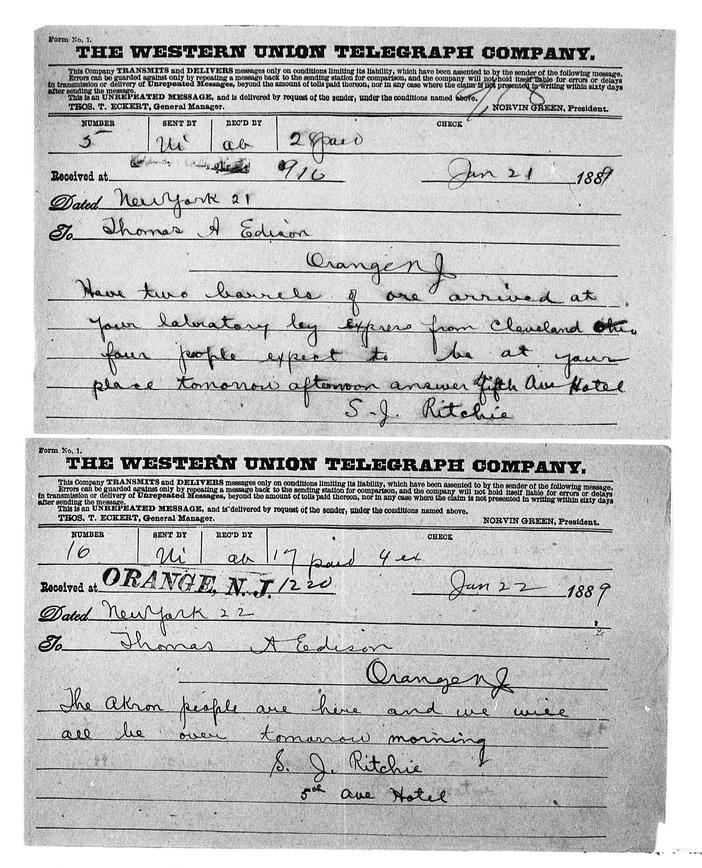

[D8952AAI], Telegram from Samuel J Ritchie to Thomas Alva Edison, January 21st, 1889

1889-01-21 -

[D8952AAJ], Telegram from Samuel J Ritchie to Thomas Alva Edison, January 22nd, 1889

1889-01-22 -

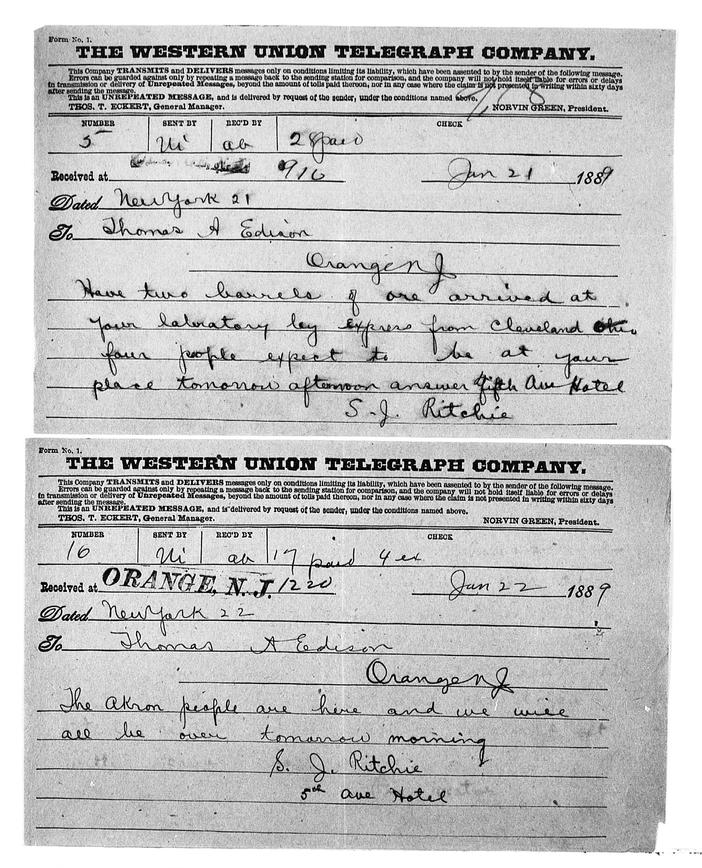

[D8952AAN], Letter from Samuel J Ritchie to Thomas Alva Edison, January 30th, 1889

1889-01-30 -

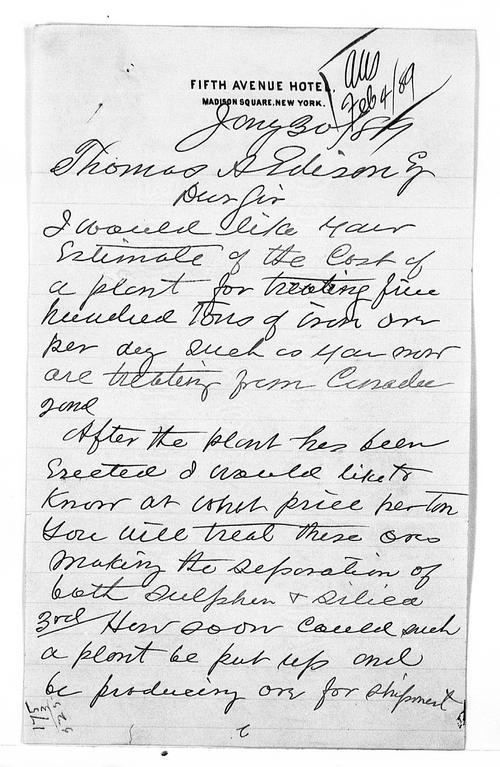

[D8952ABC], Letter from Samuel J Ritchie to Thomas Alva Edison, March 9th, 1889

1889-03-09 -

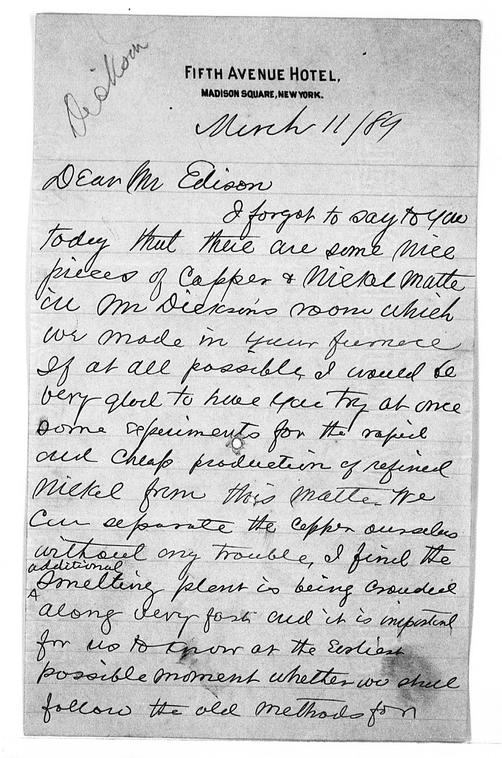

[D8952ABD], Letter from Samuel J Ritchie to Thomas Alva Edison, March 11th, 1889

1889-03-11 -

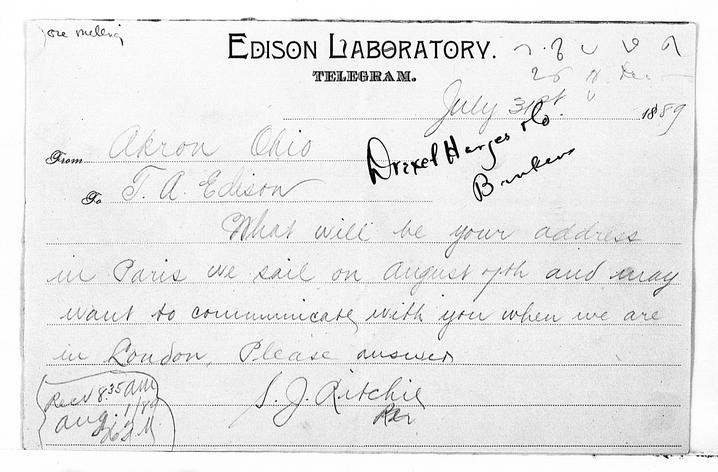

[D8952ABT], Telegram from Samuel J Ritchie to Thomas Alva Edison, July 31st, 1889

1889-07-31 -

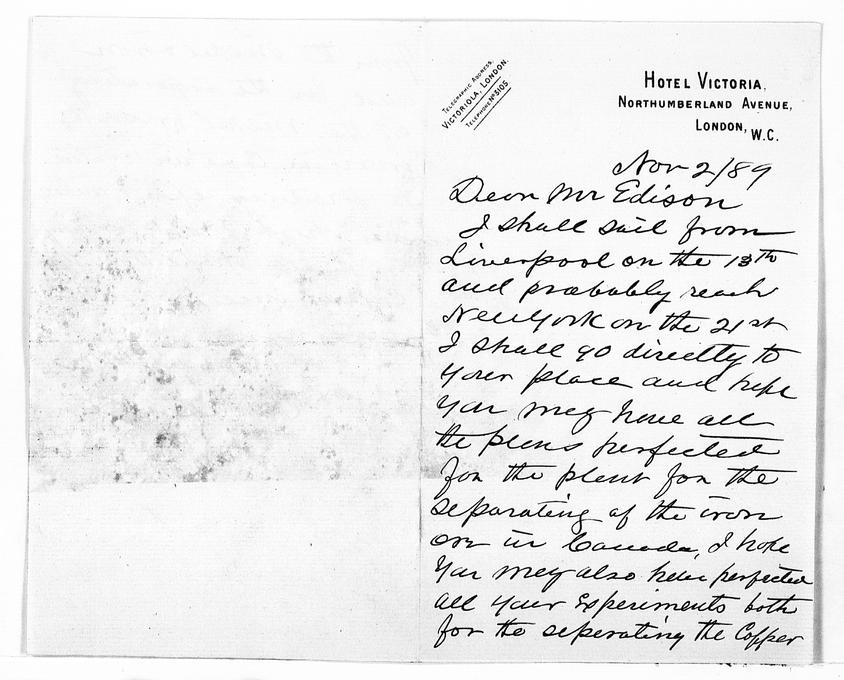

[D8952ACC], Letter from Samuel J Ritchie to Thomas Alva Edison, November 2nd, 1889

1889-11-02 -

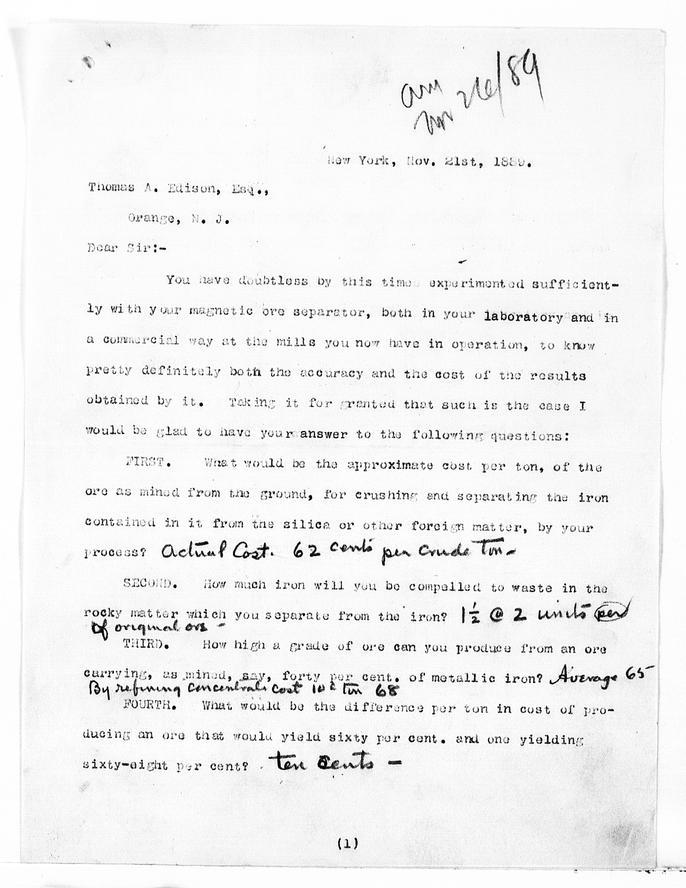

[D8952ACG], Letter from Samuel J Ritchie to Thomas Alva Edison, November 21st, 1889

1889-11-21 -

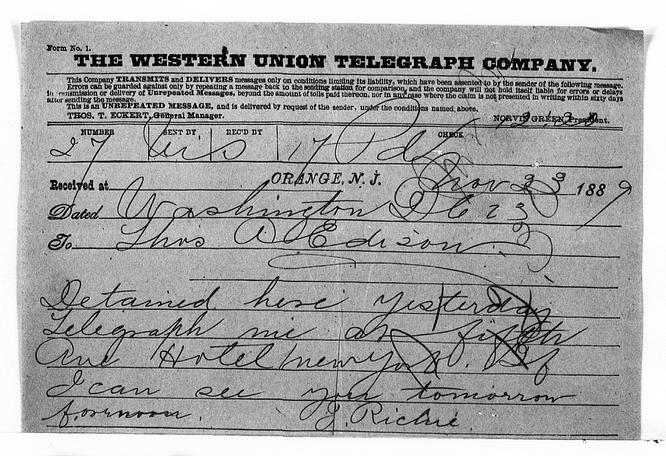

[D8952ACH], Telegram from Samuel J Ritchie to Thomas Alva Edison, November 23rd, 1889

1889-11-23 -

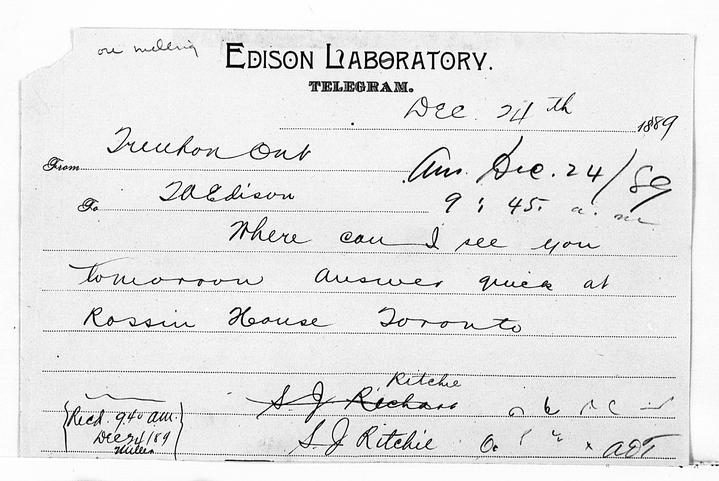

[D8952ACN], Telegram from Samuel J Ritchie to Thomas Alva Edison, December 24th, 1889

1889-12-24 -

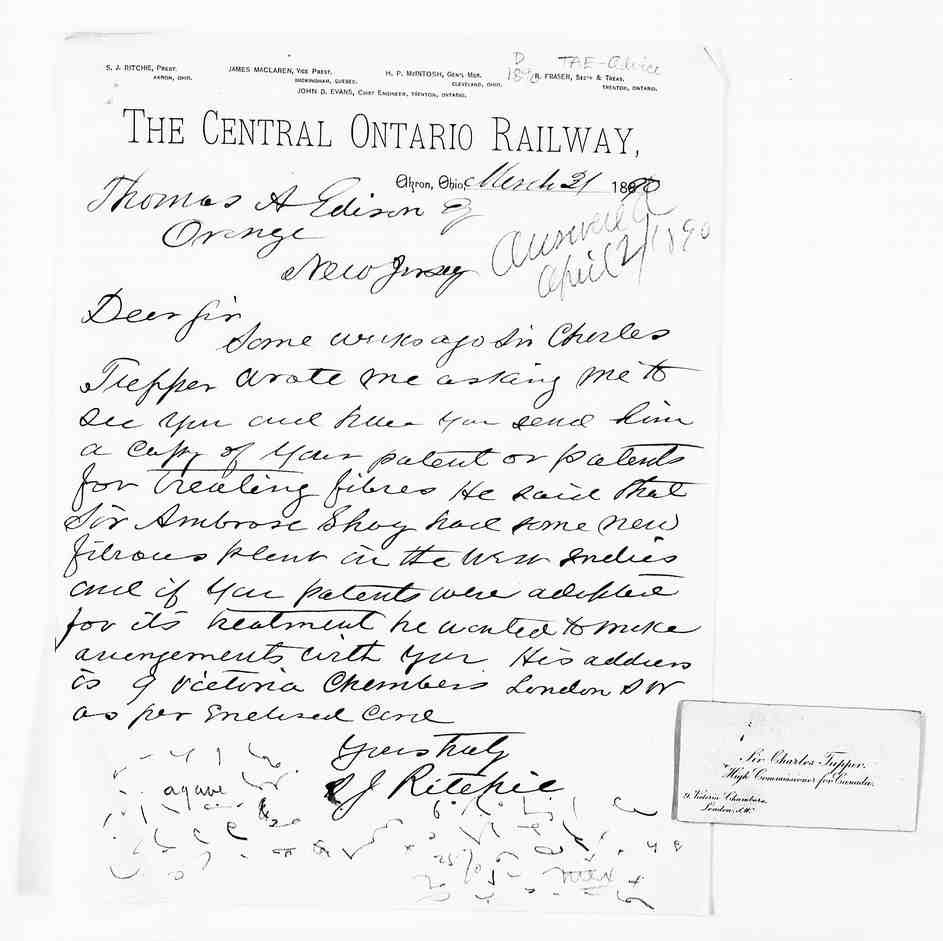

[D9028AAG], Letter from Samuel J Ritchie to Thomas Alva Edison, March 31st, 1890

1890-03-31 -

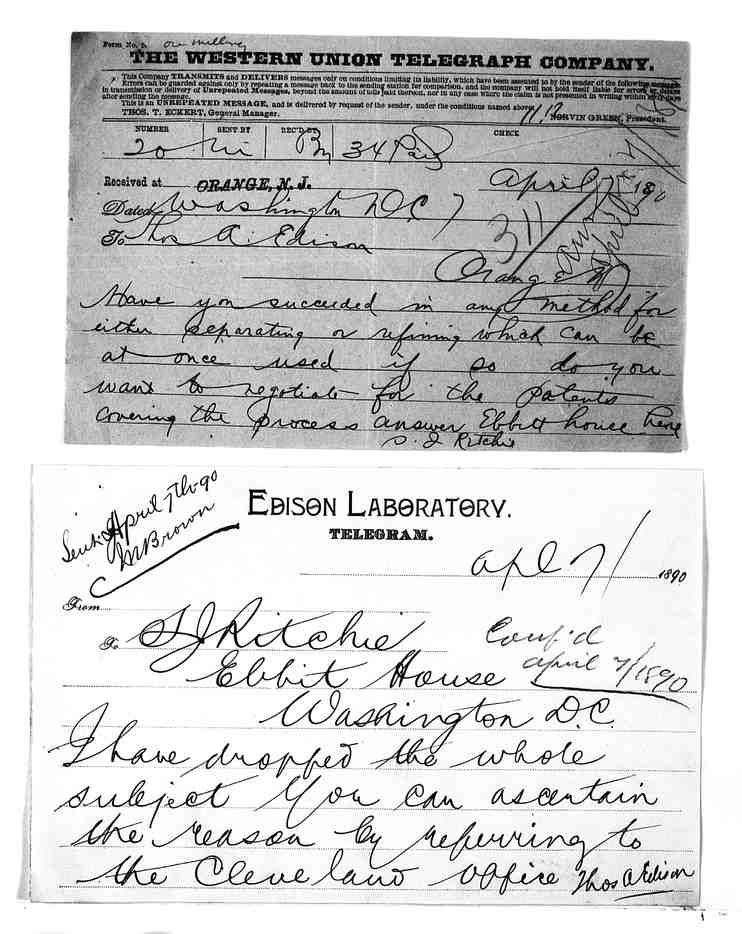

[D9047AAN], Telegram from Samuel J Ritchie to Thomas Alva Edison, April 7th, 1890

1890-04-07 -

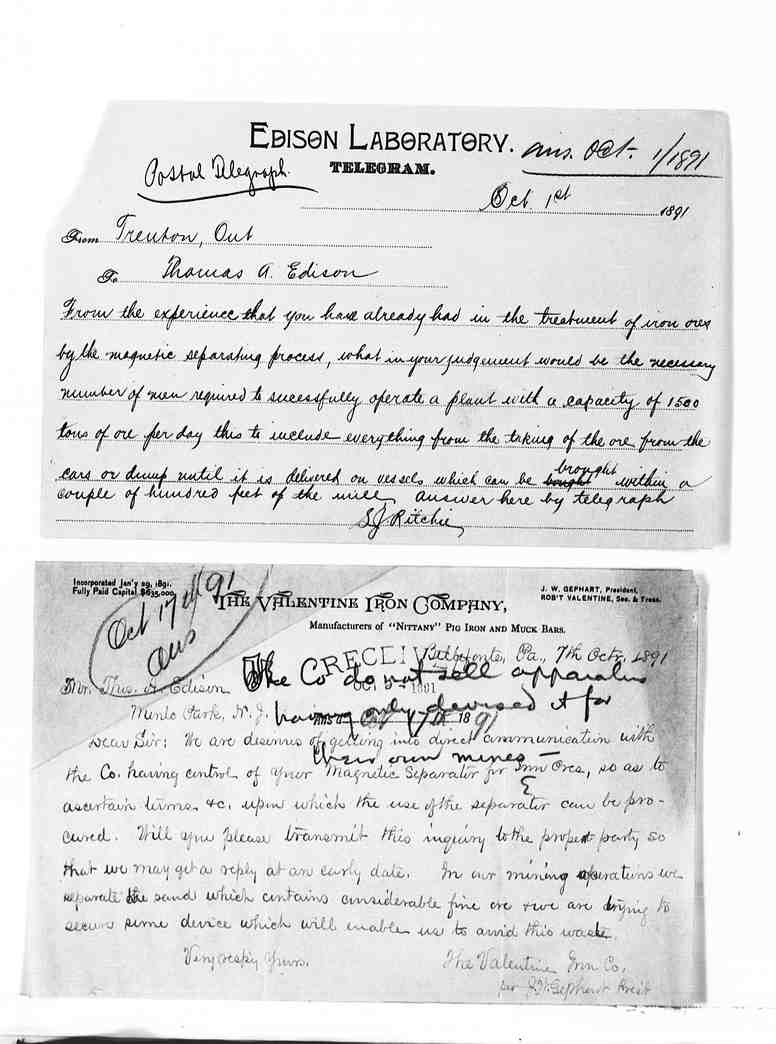

[D9134ABP], Telegram from Samuel J Ritchie to Thomas Alva Edison, October 1st, 1891

1891-10-01